Made in Italy

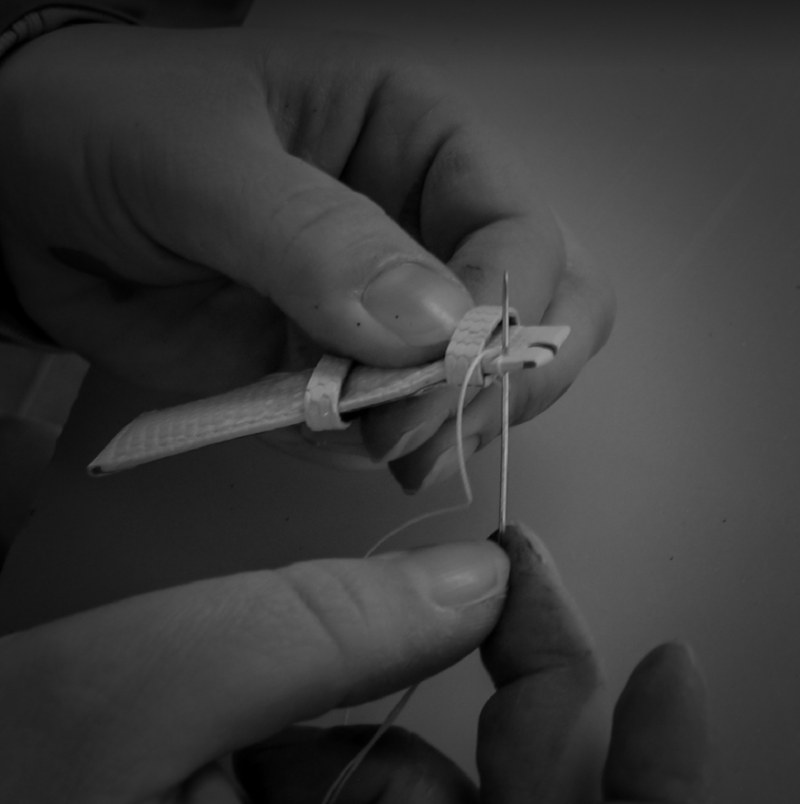

We work with the care and passion of Italian artisans, ensuring the highest quality and precision through industrial production. We combine traditional construction methods with modern technologies to create unparalleled watch straps.

Our products are made exclusively in Italy by Italian professionals. Every step of the process happens in our headquarters in Vicenza.

100% Italiano

Traceability controlled by the Italian Chambers of Commerce

Traceability Code n°UFL0118A.

See www.tfashion.camcom.it

We are a flexible company that adapts to the needs of our customers in terms of structure, organization and operating units. If necessary, we collaborate with external production sites that operate with our same quality standards. All comply with Italian and European regulations on tax, trade unions and workplace safety.

Our production chain is certified as “made in Italy” by the Vicenza Chamber of Commerce.

Innovation

CNC

AUTOMATION

3D

DESIGN

Research & Development

Quality comes first. That’s why we only use the finest, first choice leathers from the world’s best tanneries.

We are constantly engaged in the search for new materials and new treatments in order to stay ahead of market trends — and to offer our customers the very latest designs.

Eco-sustainability

We exclusively use biodegradable tanned leather that uses the patented COSMOWHITE ™ method. Eco-sustainability is a company value we strongly believe in. Choosing materials and products certified according to the strictest regulations is our ethical responsibility, and a promise we make to our customers, our collaborators, and our future.

Our eco-sustainable, hypoallergenic and heavy-metal-free straps do not release toxic substances — protecting both your health and the environment. We make products of the highest quality, using extremely versatile ecological leather that offers extraordinary luxury and durability.

We also use heavy-metal-free leathers derived from a tanning process that forgoes metal salts. What does that mean? We offer leathers with a total content of iron, aluminum, chromium, titanium and zirconium of less than or equal to 1,000 ppm (0.1% mass of each metal / total dry weight). This type of tanning guarantees low concentrations of formaldehyde, phthalate, chlorine paraffins and the absence of solvents in the finish. These production principles are the basis of a qualitatively excellent product that offers greater elasticity, softness, versatility.

Our products comply with the REACH regulation (Registration, Evaluation, Authorization, Restriction of Chemicals). Therefore, they’re hypoallergenic and free of substances harmful to your health. All reptile skins and / or other species threatened with extinction or exploitation adopt the CITES (Convention on International Trade of Endangered Species) certificate, limiting the worldwide trade thanks to the constant monitoring of protected species.